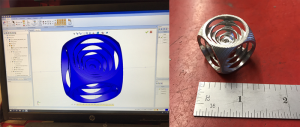

James Shorkey is a longtime manual machinist in Colorado that is turning a new leaf and conforming to CNC machining. That’s why he got BobCAD for him and his intern. In a twist of irony, his new intern is teaching him about CNC machining while James is teaching him some manual machining. “My intern uses both BobCAD & Solidworks. I am getting better with my BobCAD-CAM software all the time, learning tricks, watching the tutorials. I think in a few years here I will have it mastered. I do a lot of work for the students with their research projects. There was another shop (in town), but it’s now an empty building because the owner retired. I drive BobCAD on a Bridgeport Mill with a Fadal control & in a couple of weeks, I’m getting a Ganesh CNC 2 axis Lathe with Fadal as well. We generate drawings and also take student drawings (importing them into Solidworks), using BobCAM to create programs, edit programs & run simulation. If it all runs smoothly on the computer screen then we are golden,” says James.

James Shorkey is a longtime manual machinist in Colorado that is turning a new leaf and conforming to CNC machining. That’s why he got BobCAD for him and his intern. In a twist of irony, his new intern is teaching him about CNC machining while James is teaching him some manual machining. “My intern uses both BobCAD & Solidworks. I am getting better with my BobCAD-CAM software all the time, learning tricks, watching the tutorials. I think in a few years here I will have it mastered. I do a lot of work for the students with their research projects. There was another shop (in town), but it’s now an empty building because the owner retired. I drive BobCAD on a Bridgeport Mill with a Fadal control & in a couple of weeks, I’m getting a Ganesh CNC 2 axis Lathe with Fadal as well. We generate drawings and also take student drawings (importing them into Solidworks), using BobCAM to create programs, edit programs & run simulation. If it all runs smoothly on the computer screen then we are golden,” says James.

Since James is pretty green to CNC machining, he is encountering a lot of learning curve. But regardless of the curve, he is diving right into CNC machining and taking advantage of our tutorial videos. “I have been a manual machinist for 50 years. It’s a big learning curve for me but I am picking it up and I feel good about it… no complaints. I do both 2D and 3D work. It (BobCAD) has opened up a whole world of possibilities that we couldn’t do with manual machines,” says James.

Since James is pretty green to CNC machining, he is encountering a lot of learning curve. But regardless of the curve, he is diving right into CNC machining and taking advantage of our tutorial videos. “I have been a manual machinist for 50 years. It’s a big learning curve for me but I am picking it up and I feel good about it… no complaints. I do both 2D and 3D work. It (BobCAD) has opened up a whole world of possibilities that we couldn’t do with manual machines,” says James.

Although James hasn’t made anything yet on his machine using BobCAD, his intern does quite a lot. His intern has a side business where they take Japanese motorcycles and turn them into bikes that are more cafe racer styled. “He did a lot of really cool fairings in sheet metal with BobCAD. He engraved them with his company logo, cut out all the openings and then cut out all the crease lines where they broke. They are just beautiful… he powder coats them too; it just looks really nice! We also have BobART so that really helps us engrave intricate designs,” says James.

After being a manual machinist for half a century, I was curious about what James really liked about his new BobCAD-CAM system. He tells me, “I like the ease in which we can do 3D programming as opposed to programming it on a machine by hand...it is phenomenal. It has saved me a ton of programming time. We don’t do a lot of production here, we are more of a prototype & job shop. BobCAD saves us a lot of headaches as far as multiple hole drillings and things like that go. It really saves these old shoulders!” As I ask all of our customers at the end of our interviews, I asked James if he would ever recommend BobCAD’s CNC software to other students or schools. James says, “Oh, I would! Just for the support that you get from the BobCAD system. When we first purchased BobCAD, we had an issue with our license code. A nice guy by the name of Cody connected computers with me and had me going in a few moments. That right there is worth it alone for me.”

After being a manual machinist for half a century, I was curious about what James really liked about his new BobCAD-CAM system. He tells me, “I like the ease in which we can do 3D programming as opposed to programming it on a machine by hand...it is phenomenal. It has saved me a ton of programming time. We don’t do a lot of production here, we are more of a prototype & job shop. BobCAD saves us a lot of headaches as far as multiple hole drillings and things like that go. It really saves these old shoulders!” As I ask all of our customers at the end of our interviews, I asked James if he would ever recommend BobCAD’s CNC software to other students or schools. James says, “Oh, I would! Just for the support that you get from the BobCAD system. When we first purchased BobCAD, we had an issue with our license code. A nice guy by the name of Cody connected computers with me and had me going in a few moments. That right there is worth it alone for me.”

You're one click away from subscribing to BobCAD’s YouTube channel. Click the link below for tips, how-tos and much more!